RXT-G

Powered by 30 6v nominal Nickle-Iron (NiFe)

Edison batteries mirroring the original

TEVan traction pack.

===

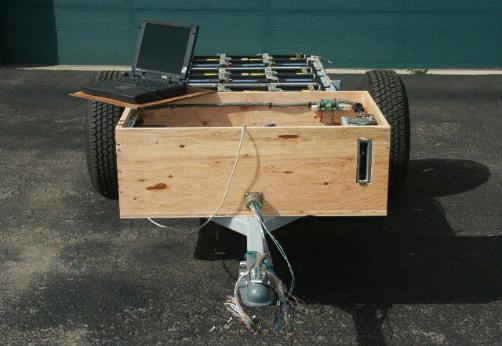

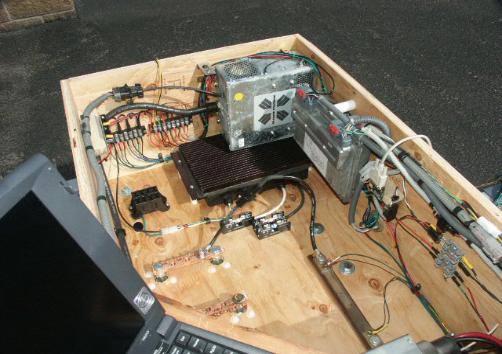

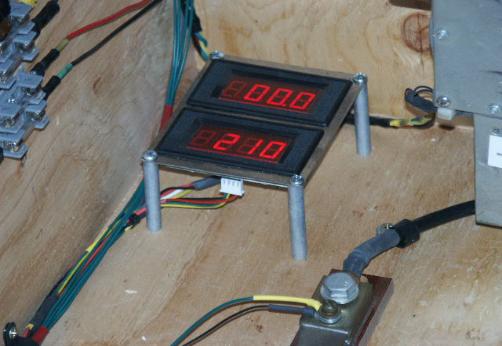

We have heard (c2005) much talk about the potential development

of range extending trailer applications in theory, but have

not found anyone verifying the concept

by building a prototype.

Since we had an entire extra set of EP NiFe 200 AH batteries

we decided to give the RXT-B (range extending trailer - battery) a real

life test. Of course, one should always start with the theoretical, so

here is a bit of data to share.

The TEVan has a single-string 180v pack that consists of 30

200AH modules and weighs 1,650 lbs. The vehicle has a

total OEM weight of 5,000lbs and a published 80 mile range. By

adding a RXT-B as a second, parallel string, we increase

the overall vehicle weight by 1,650lbs.

The question is what additional range would we be expected

to achieve with the second string?

The math equation would be as follows: “from the relation

range [km] = capacity [kwh] x 250 / mass [kg] ^ 0.6I”.

Therefore, doubling the energy capacity while

increasing weight by 33% gives a range increase of X 1.68 or a

135 mile range. 135 miles on a TEVan would be

impressive. So we are off to try the experiment.

The following photographs represent the project status

from inception to present, c2005, and although it is not

yet completed, it is getting close.

===

---> Additional pictures below <---

===