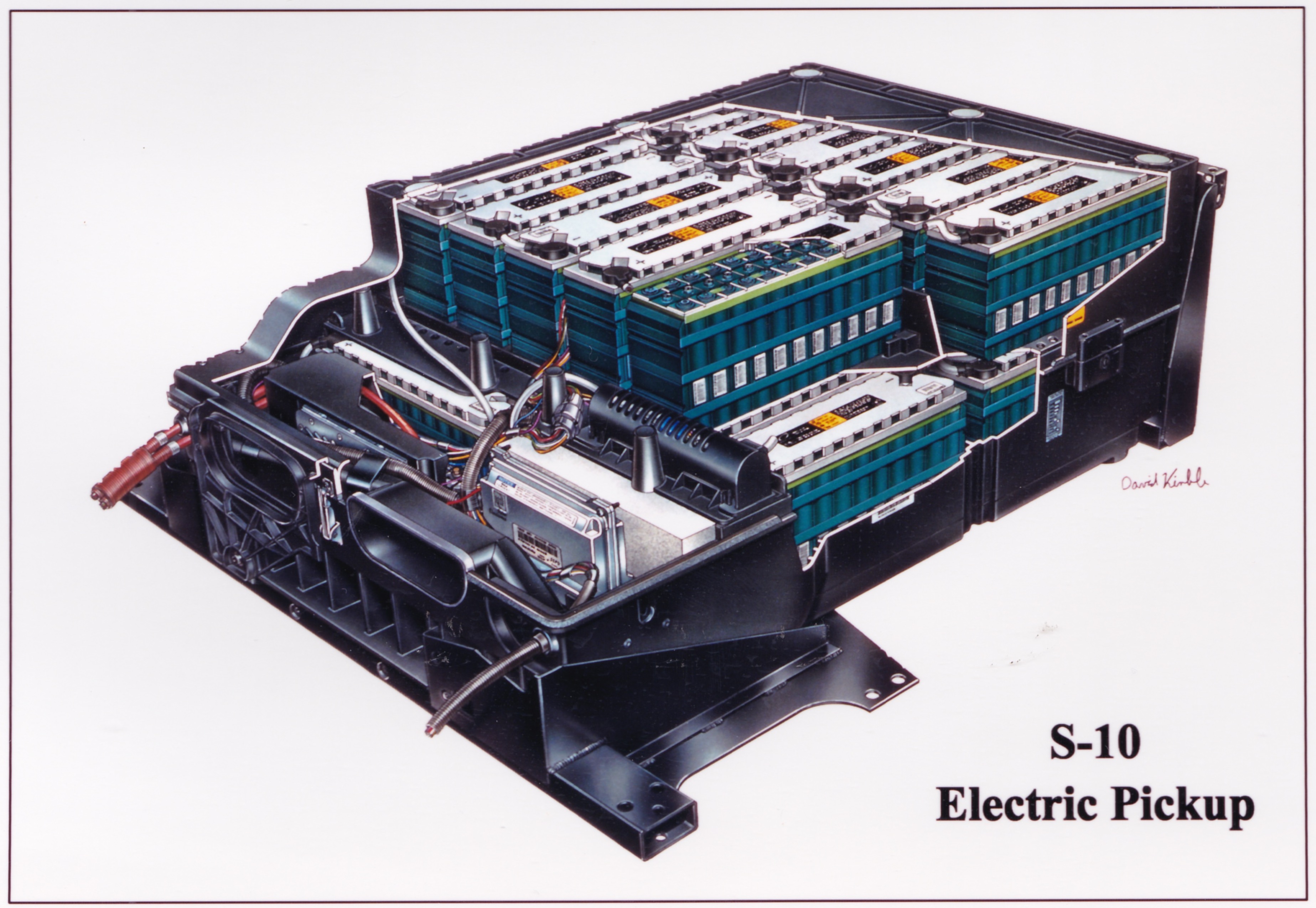

Press photo from the 1998 Detroit Auto Show

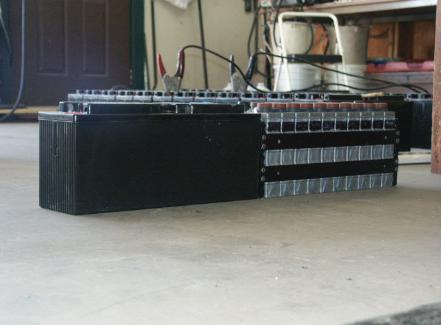

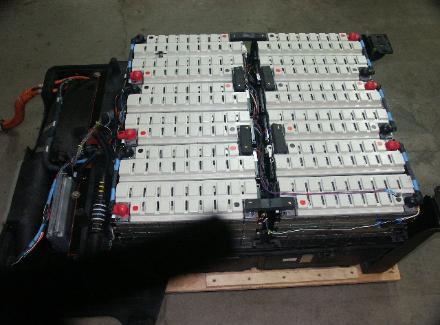

The battery box removed from the S10E

Here is a look at the Panasonic EC-1260U PbA modules to be removed

Another view with covers removed. We suspect that this was the vehicles second set of batteries, with a set of original Delphi units preceding them.

When we acquired this vehicle the batteries had sat uncharged for +/-3 years. We left them on a slow charge for two weeks to see if any of them might come back to life. A few showed signs of life, but none would would become viable

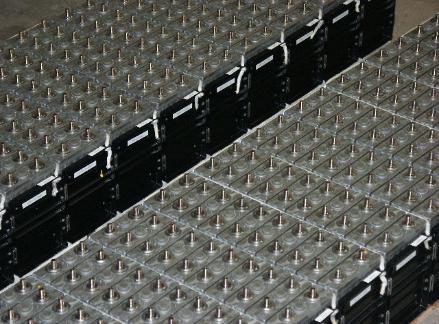

A picture of the original bottom tray of the battery box. Note the thermal holes/passage designs, sending the are around the modules

Here we are test fitting the EV-95s to the upper tray

Comparing the Gen2 PbA and the EV-95

This is the battery box main frame structure

The bottom of the box without the bottom tray installed. Note the air passages. They allowed later modifications to the ventilation systems that will be noted in pictures to follow.

The bottom tray has been added here

For comparison, we now see the new ventilation holes in this shot. The EV-95s are cooled from in-between the cells rather then from the sides of the PbA design. Note some passages had to be opened sideways and others lengthwise due to the air flow characteristics previously mentioned

Preparing the EV-95s for installation.

Here we are test fitting an EV-95, checking for top, side and length fitting & ventilation alignment. One down, 25 modules to go

More fitting and working out the harness locations

Note the white plastic battery tops. These were used on early EV-95s. They helped with the double stack design of the the new box so we used them for this application, too

Here the support framing rails have been added, and although not visible the original HV (high voltage) cabling has been redesigned due to the different terminal locations

This is the top tray showing the modified ventilation system. Upon initial testing the cooling capacity was much improved. Again we see where certain vents had to be drilled sideways to adjust for the support framing blocking airflow from below

Here is an installed angle on the top tray

26 down, and lots of details still ahead

Ready to be closed up and reinstalled. Note the additional orange harness for 4 added native EV-95 temp sensors and one additional native pressure sensor. Each of the new sensors mirror the stock Rav4-EV parts & configuration

Cleaned and ready for installation

It takes us about two (2) hours working alone to reinstall the box from start to finish. That is rather reasonable considering the 5th grade leverage techniques and +/-1,600lbs to skoot around. All a good challenge

Here is a picture of the the traction pack completely reinstalled

Back in one-piece after two months of planning and work. The last phase of this project will be to determine which of the existing BPCM calibrations would be safest, with additional monitoring, to charge and care for the Panasonic EV-95 NiMH modules