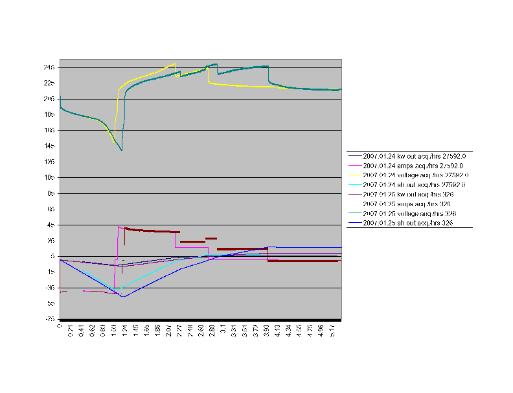

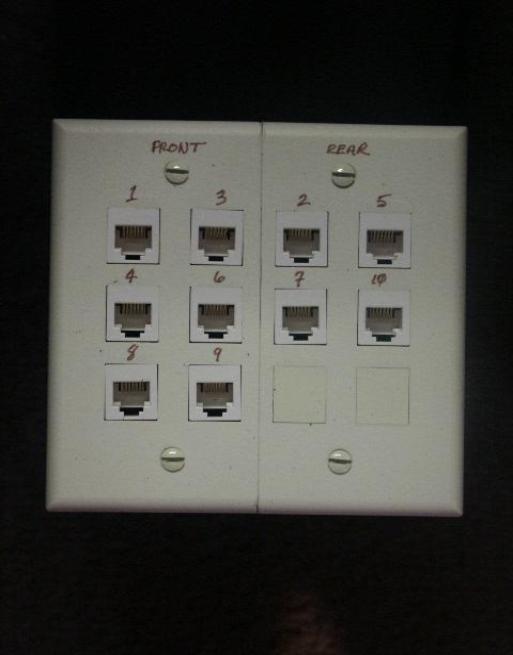

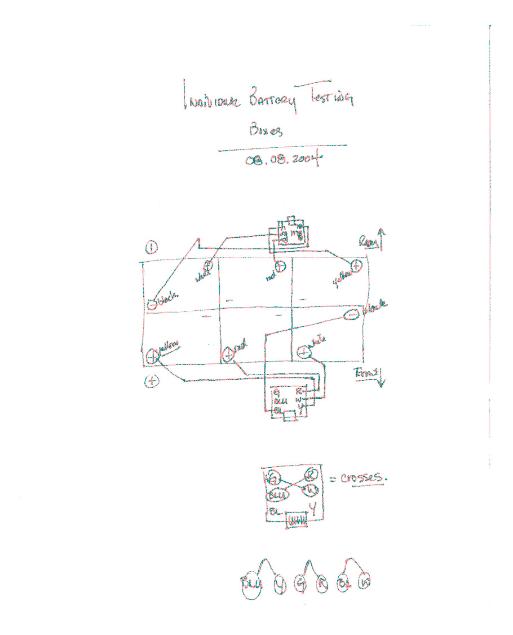

Individual Battery Monitoring Systems

===

---> Additional pictures below <---

===

1993 Dodge TEVan

('93) only - production 56 units - <12 known to exist c2022

BEV designed by Joint Venture between Dodge & GE c1993

- --> 30kWH capacity traction pack - 0.83 gallon gas equivalent

- --> 80 mile nominal range

- --> 50kW / 36hp equivalent SEPEX traction motor

- --> 2 speed semi-automatic EV transmission